Turning wastewater into potable water requires a number of cleaning steps, one of which is the application of Activated Carbon (AC) to control potable water taste, colour and odour.

GAC (Granular Activated Carbon) is typically used in a water treatment plant after the coagulation and sedimentation processes. Moreover, water is often disinfected before it passes through the GAC in order to prevent nuisance biological growths. The carbon bed also functions as a granular filter medium for removing particulates.

The characteristics of the carbon material (particle and pore size, surface area, density, and hardness) influence the efficiency of adsorption. The characteristics of the chemical contaminant such as the tendency of the chemical to leave water are also important. If several compounds are present in the water, strong adsorbers will attach to the carbon in greater quantity than those with weak adsorbing ability.

During the purification of waters, impurities collect in the pores of the carbon. After a while, the carbon becomes full and contaminants begin to break through the GAC bed. The spent carbon must be regenerated so that it can be re-used. This involves the removal of contaminants from the carbon. Regeneration is far more economical than buying virgin carbon.

Various regeneration techniques have been developed over the years, including thermal, chemical, solvent, vacuum, biological, and wet (steam) oxidation methods. Of these methods, thermal regeneration is the most common.

The thermal regeneration of spent carbon is one of the most important factors involved in the economic consideration of activated carbon treatment of water. The adsorbed organic materials are volatilized or oxidized at a high temperature during this process. Ideally, this would be done in such a manner that a maximum amount of adsorbed organics are driven off with a minimum change in the adsorptive properties of the carbon. The success of regeneration depends on a number of factors, including carbon temperature, residence time at the required temperature, and the composition of the hot gas mixture.

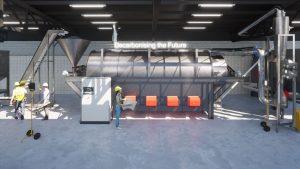

The most positive carbon regeneration results are accomplished through thermal means. The two most widely employed thermal equipment types today are rotary kilns and multiple-hearth furnaces. In rotary kilns, carbon moves concurrent to a mixture of volatile gas and superheated steam. This is the method employed by Carbon Clean and reliably restores the adsorptive capacity of the regenerated carbon back to that of the new carbon.