In this video we’re sharing how pyrolysis technology can be used, as part of a circular process, to recover precious metals from electronic waste.

Why do this?

Each year over 50million tons of electronic waste is produced worldwide. E-waste is the fastest growing waste stream in the world and currently less than 20% of it recycled. It is estimated that at least ($10bn / £7.9bn / €9.46bn) worth of precious metals are dumped every year in the growing mountain of e-waste.

Why use pyrolysis technology?

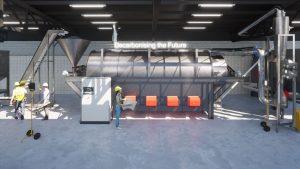

The clean separation of components from the boards is one of a number of key steps in a larger process which makes the recovery of precious metals from e-waste possible. In this step we take shredded circuit boards and use pyrolysis technology to apply a consistent low temperature to the boards. Heat from the process causes the solder which holds the components and boards together to melt. The tumbling action of the material inside the rotating tube generates enough force to separate the surface mounted components from the boards once the solder has been melted. A proof of concept at this scale allows us to predict, with a high degree of accuracy, what the results may look like in a commercial scale pyrolysis process. In this instance we’re creating and capturing data from a trial with a small amount of material (0.35kg) to model a commercial scale process that will be used to recover precious metals from thousands of tons of e-waste every year.

What else can pyrolysis technology be used for? Watch our video “Data Centre Powered By Waste” here: https://youtu.be/xef13P0EWds